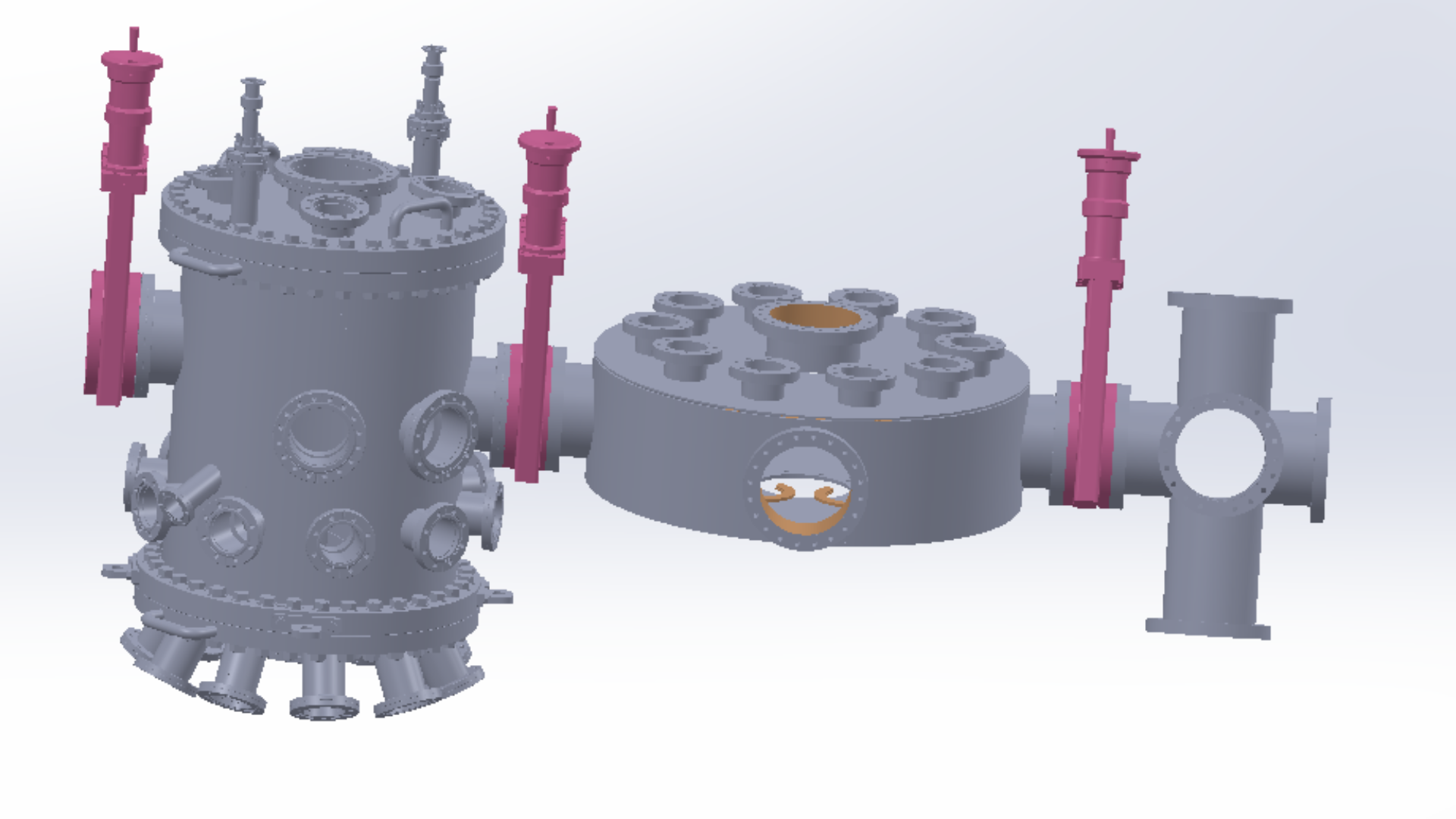

VESCO-Ultima 310 MBE SYSTEM

MBE system for 3-4 inch samples with 10 ports for combination of 10 sources and effusion cells. This system is exceptionally versatile with high functionality suitable as a research and production tool for III/V, II/VI, and other materials. The VESCO-ULTIMA 310 is the state-of-the-art MBE system which enables growth for many applications with fully automated wafer transfer options.

Exceptional Quality Through Advanced Manufacturing

- Wafer size 2-4 inches with face down geometry

- Wide range of 10 sources options (valved crackers, plasma source, and effusion cells)

- Substrate heater up to 1200°C

- In-situ characterization capabilities (RHEED, QMS, flux monitor, pyrometer, and Ellipsometry)

- High capabilities for growing different materials in one chamber

- View ports with integrated heaters, LED, and Cameras

- Easy to move, operate, and install (three vacuum chambers on two separate carts)

- Small footprint, space, minimum power and utilities consumption

- High reliability and efficacy

- Easy wafer loading, unloading, and transfer

- Automatic or manual operation

- Separate and movable flux monitor

- Full electronic cabinet

- Well-organized wires and cables

- Competitive price

- Efficient UHV pumping stations with base pressure less than 5 x 10-11 mbar

- Optimized growth geometry to achieve long growth campaigns and high layer uniformity

- LN2 cooling shroud

Technical Data

| Growth chamber size | 22” OD, 24” height |

|---|---|

| Buffer chamber size | 28” OD, 10” height |

| Load lock chamber size | 6-way 8” cross |

| Wafer cassette size | Two cassettes, 8 sample holder each |

| Buffer chamber capacity | 8 sample holders 36 degrees apart |

| Substrate size | 2”-4” |

| System pumping stations | Growth chamber: Cryo, ion, and TS pumps Buffer chamber: Ion and TS pumps Load lock: turbo and scroll pumps |

| Cooling shroud | LN2 or other cooling liquid |

| Substrate heater temperature | Up to 1200 C |

| Bakeout temperature | Up to 200 C |

| Sources port sizes | 4.5” CF flange |

| Types of sources | Effusion cells, valved crackers, RF plasma sources, e-beam sources, sublimation sources, and gas injector sources |

| Shutters | Magnetically coupled liner shutters |

| In-situ monitoring | Ion gauge, QCM, pyrometer, RHEED, QMA |

| Sample transfer | Robot transfer arm with azimuth and z travels |

| Service | System installation and acceptance testing |

| Training | By MBE experts |