VALVED CRACKERS

Description:

VESCO-NM corrosive materials valved cracker is used, in MBE growth, to crack reactive materials with high-vapor pressure such as Sb, Zn, Se, Cd, CdTe, Te, and Mg. In this source, crucible and cracking tube and valve assembly are

ALL manufactured from PBN to avoid any corrosion. The source has

ONLY two integrated heaters for bulk and cracking zones, without heat separation or gap, to avoid materials condensation and to reduce the cost by using less number of power supplies and temperature controllers. Easy materials loading process is achieved using either the removable valve assembly or through the loading flange. The PBN valve assembly is designed to achieve fast flux stabilization, excellent uniformity across substrate, and quick and complete shut-off to minimize materials wasting. The valve can be controlled by other vendors’ Automated Valve Positioners. Valve travel distance limits are secured by internal mechanisms to avoid any possible adjustment-related damages or stress on the PBN parts.

Key Features:

Compatible with all MBE systems- Used for corrosive materials such as Sb, Zn, Se, Cd, CdTe, Te, and Mg

- 300 CC PBN crucible

- Integrated heaters assembly (no heat gap- no material condensation)

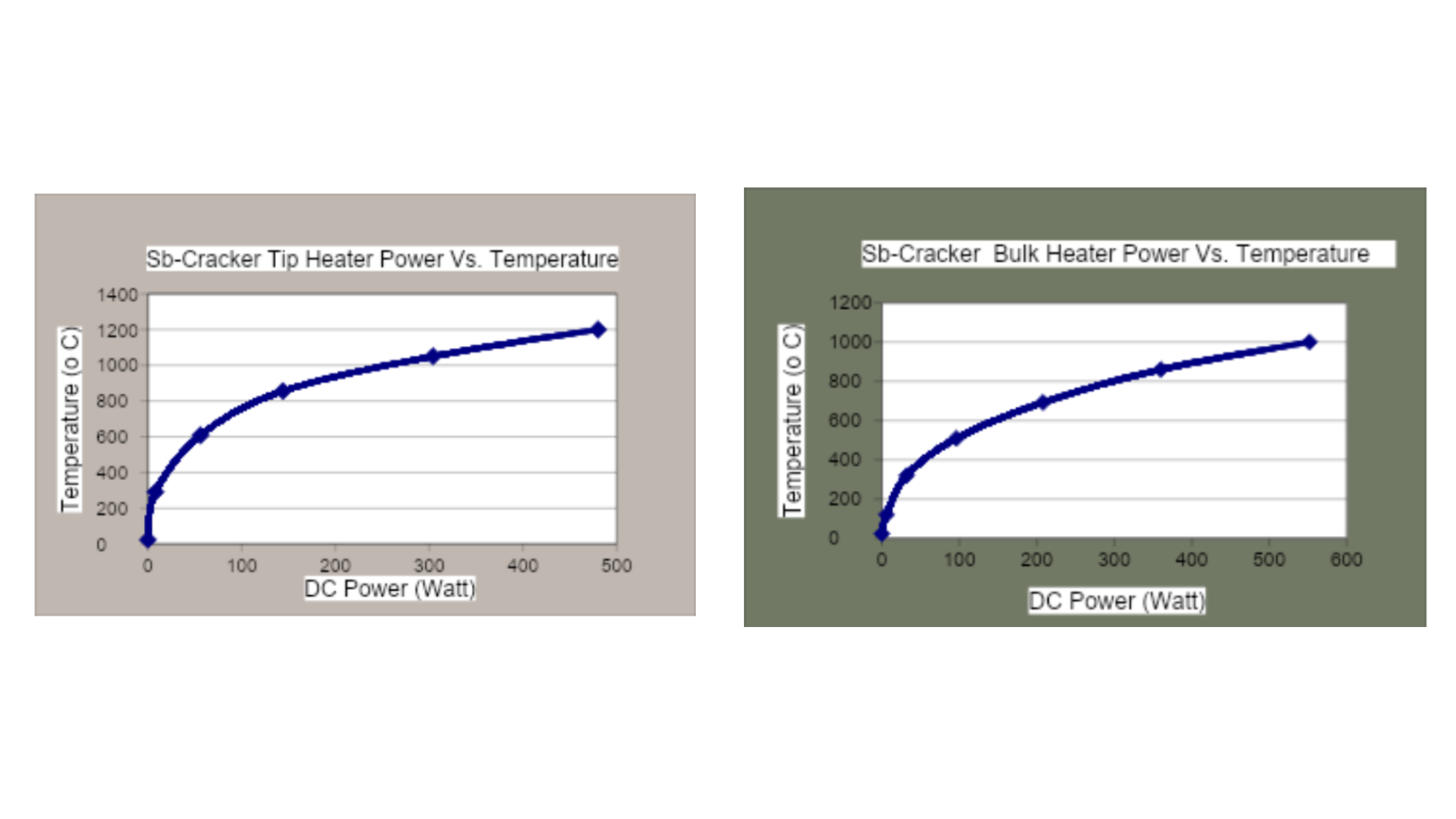

- Tip heater 600-1200 C

- Bulk heater: 200-800C

- Out gassing temperature: 1350-14500 C

- High flux uniformity

- Excellent flux stability

- Dynamic flux range: Two-Three orders of magnitude

- Easy to maintain and to charge

- 4.5” mounting flange (other on request)

- Length inside vacuum: 12.85”-Total air length: 24.50” (other as required)

- Valve travel distance: 0.400”

- Number of turns: 18 turns

- Open position: CW - Close position: CCW

- Valve position is controlled either manually or automatically

- Charge material size: 0.470” or less

- Can be operated in cracked or un-cracked mode

- Water cooling: Double wall for bulk zone. Optional: cooling coil for cracking zone

- Power Supplies: Only two power supplies and two temperature controllers units are required

- Flexible orientation installation

- One power feedthrough (4 pins) and one thermocouple feedthrough (4 pins)

For Corrosive and Non-Corrosive Materials

(As, Sb, Zn, Se, Cd, CdTe, Te, and Mg)

Testing and Results: